Nanoscale 3D Objects

A technique has been developed that allows three-dimensional objects of nearly any shape to be shrunk down to nanoscale size. And it works with any number of useful materials, including metals, quantum dots and even DNA.

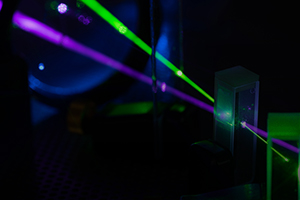

Known as “implosion fabrication,” the process begins by patterning a scaffold from highly absorbent polyacrylate (commonly found in the absorptive lining of diapers) with a laser. The structure is soaked in a solution of fluorescein molecules, which will attach to the scaffold when exposed to laser light. The fluorescein is attached using two-photon microscopy, which enables precise targeting of specific locations deep within the scaffold. These act as anchors for binding other types of molecules.

Once the molecules are attached, the entire structure is shrunk down through the addition of an acid that blocks negative charges in the polyacrylate gel, causing it to contract. The object then shrinks down to one-tenth of its original size in each direction (for an overall 1,000-fold reduction in volume). The technique can currently create objects as small as one cubic millimeter in size.

According to the developers, the equipment required to shrink three-dimensional objects to nanoscale size is already available in many research laboratories, so the potential applications are vast and could include specialized optics for cameras, microscopes. and endoscopes, or nano-sized parts for robots.

For information: Edward Boyden, Massachusetts Institute of Technology, Department of Biological Engineering, 77 Massachusetts Avenue, Cambridge, MA 02139; phone: 617-324-3085; email: esb@media.mit.edu; website: http://web.mit.edu/