4D Printed Ceramics

4D printing refers to a process for fabricating “programmable” matter, in which a three-dimensional printed object is engineered to react with its environment and transform over time in a predictable manner. For example, a hydro-reactive polymer can be 3D printed to assume one shape when dry and a totally different shape when immersed in water. Depending on the material used, the structures can be made to respond to a variety of stimuli including heat, light or other external physical forces (stretching or compression). Most of them are made from flexible materials such as plastics, cellulose composites and metals.

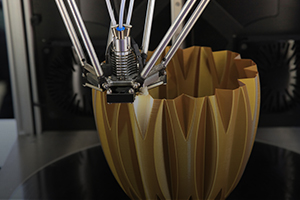

Recently, material scientists reported using ceramics to produce 4D structures that, when heated, form a hard, rigid material that is extremely strong and heat resistant. A ceramic “ink” was developed by mixing ceramic nanoparticles with silicone rubber. The ink was used to print stretchy, sheets which were then stretched around a series of joints to form a variety of shapes. When heated to 1000 degrees Centigrade they were transformed into rigid ceramic structures.

Materials such as these could be used to produce strong, complex parts for rockets, satellites, engines and electronic devices that will be exposed to extreme temperatures.

For information: Jian Lu, City University of Hong Kong, Department of Mechanical Engineering, Tat Chee Avenue, Kowloon, Hong Kong, SAR; phone: +852-3442-9811; email: jianlu@city.edu.hk; Web site: https://www.cityu.edu.hk/