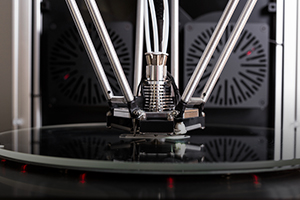

3-D Printing with Metal

The ability to use metals for 3-D printing has the potential to revolutionize multiple industries by increasing the flexibility of design and product customization while eliminating economy-of-scale constraints. But currently, only a few alloys are suitable for the process because the dynamics of melting and cooling cause metals like aluminum to weaken and crack.

The ability to use metals for 3-D printing has the potential to revolutionize multiple industries by increasing the flexibility of design and product customization while eliminating economy-of-scale constraints. But currently, only a few alloys are suitable for the process because the dynamics of melting and cooling cause metals like aluminum to weaken and crack.

Recently, materials scientists discovered that introducing zirconium nanoparticles (also referred to as nucleants) into the metal being printed resolved this issue by providing a crystalline framework that controls the solidification process. In particular, they found that high-strength aluminum alloys could be 3-D printed successfully using selective laser melting techniques.

This method could also be applied to other alloys and for a broad range of 3-D printing processes, including electron-beam melting or directed-energy deposition. One of the first applications for the new materials is likely to be in the aerospace industry, where 3-D printable metals could be used to build lighter, faster aircraft.

For information: HRL Laboratories, 3011 Malibu Canyon Road, Malibu, CA 90265; phone: 310-317-5000; fax: 310-317-5483; website: http://www.hrl.com/