Expanding the Boundaries of 3-D Printing

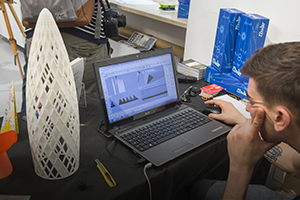

Leave it to the creators of AutoCAD to come up with the next generation of 3-D printers. The latest addition to their line of 3-D software solutions is knows as Project Escher, a control technology that pushes the boundaries of 3-D printing to new levels.

Leave it to the creators of AutoCAD to come up with the next generation of 3-D printers. The latest addition to their line of 3-D software solutions is knows as Project Escher, a control technology that pushes the boundaries of 3-D printing to new levels.

Although conventional 3-D printing is fine for small, relatively simple projects, its speed is greatly reduced with increased size and/or complexity. Project Escher works around this bottleneck by running multiple tool paths on collaborating machines to generate much larger prototypes in a short period of time.

The whole system is designed to be modular so that printheads can be changed out with other types of tools to perform specific tasks. For example, some could be printing while a milling head cuts away those portions of the structure that are only needed during printing and a robotic arm adjusts the positioning of the part. The bottom line is that by distributing tasks among independent tools linked together by parallel-processing systems, larger prototypes can be created in less time than ever before. Although it’s still under development, a commercial version of the platform may be available as early as 2017.

For information: Autodesk, Inc., 111 McInnis Parkway, San Rafael, CA 94903; phone: 415-507-5000; fax: 415-507-5100; website: http://projectescher.com/